PEARL ENGINE BACKGROUND

During the 1880’s the pleasure boating public found steam engines manufactured by the Boston, Massachusetts firm of the Edward S. Clark Company reliable, capable and economical in operation. Launch style vessels were gracefully powered by Clark marine steam engines. The power requirements of industry were also served with Clark stationary steam engines.

We at the Pearl Engine Company recognized the design’s continued appropriateness. After careful blueprinting, pattern making and founding, we are pleased to offer our PEARL engines. When compared to the original Clark, the PEARL steam engines are faithful revivals of an elegant and proven performer.

FEATURES

Features of the original Clark engine are shared by the PEARL engine and include:

The unique long wishbone-shaped connecting rod decreases strain.

The inverted design places the heavier parts lower.

Large bearing surfaces increase longevity.

All stuffing boxes and adjustments are accessible from the top.

Smooth flowing steam passages cast in at the foundry simplifies machining.

The Stephenson Link reversing allows for easy reversing.

Common to all PEARL engines is high efficiency piston valves.

SPECIFICATIONS

PEARL SINGLE Cylinder Engine Specifications:

Bore and stroke is 2 ½” by 3”

Steam line is ½” IPT steam and ¾” IPT exhaust

Dimensions are 16” long, 9” wide and 22” high

Weight is approximately 86 pounds

PEARL TWIN Cylinder Engine Specifications:

Bore and stroke is 2 ½” and 2 ½” by 3”

Steam line is ½” IPT steam and 1” IPT exhaust

Dimensions are 25” long, 9” wide and 22” high

Weight is approximately 165 pounds

CAPABILITY

Powering your steam launch:

Steam boaters typically choose the PEARL single cylinder engine when powering up to a 20 foot long launch. Those powering up to a 25 foot launch choose the PEARL twin cylinder engine with its single lever reversing. PEARL engines have high torque at low speed. Their effortless and quiet operation allows for enjoyable travel on the water.

Prime mover:

When powering shop machinery, water pumps, electrical generators and mills, PEARL engines are a practical alternative source of power. Their high torque at low speed makes the PEARL an excellent choice.

COMPARE

When comparing other steam engines, note PEARL steam engines achieve their horse power and torque at low RPM. Many manufacturers over-rate and claim higher horsepower with the same bore and stroke. Look at their higher RPM requirements.

Longevity, Economy and Reliability are the hallmarks of PEARL engines.

BUILDER NOTES

Casting Kits, Complete, And Unique:

For an experienced builder with an intermediate level of skill, construction is straightforward. The included machining drawings are easy to read with typically one part per page. An assembly manual is included.

Complete Kits:

All the castings and necessary materials are also included. The kit is complete in the smallest detail. All the necessary fasteners, stock, packing and hardware are included as well. You will not have to purchase anything else. Valves, fittings, piping and lubricators are specific to your installation and not included.

Our built-up crankshaft construction uses superior materials and allows for easy alignment. The foundry cored cylinder casting simplifies machining. The castings are steel shot blasted and not rough ground.

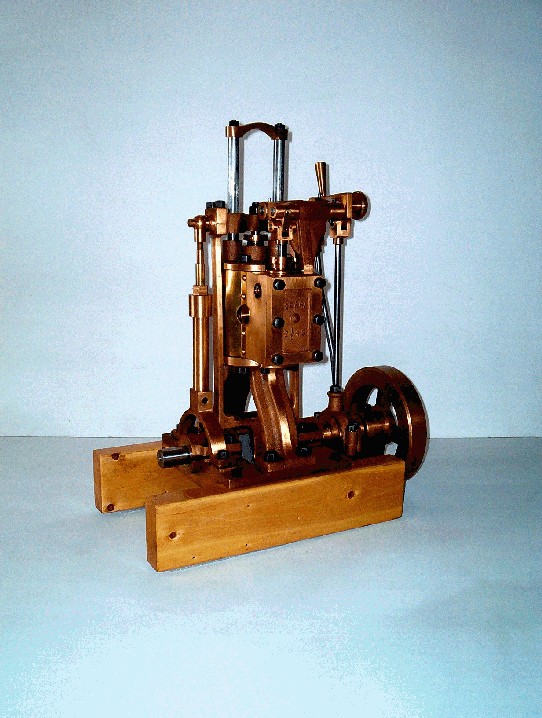

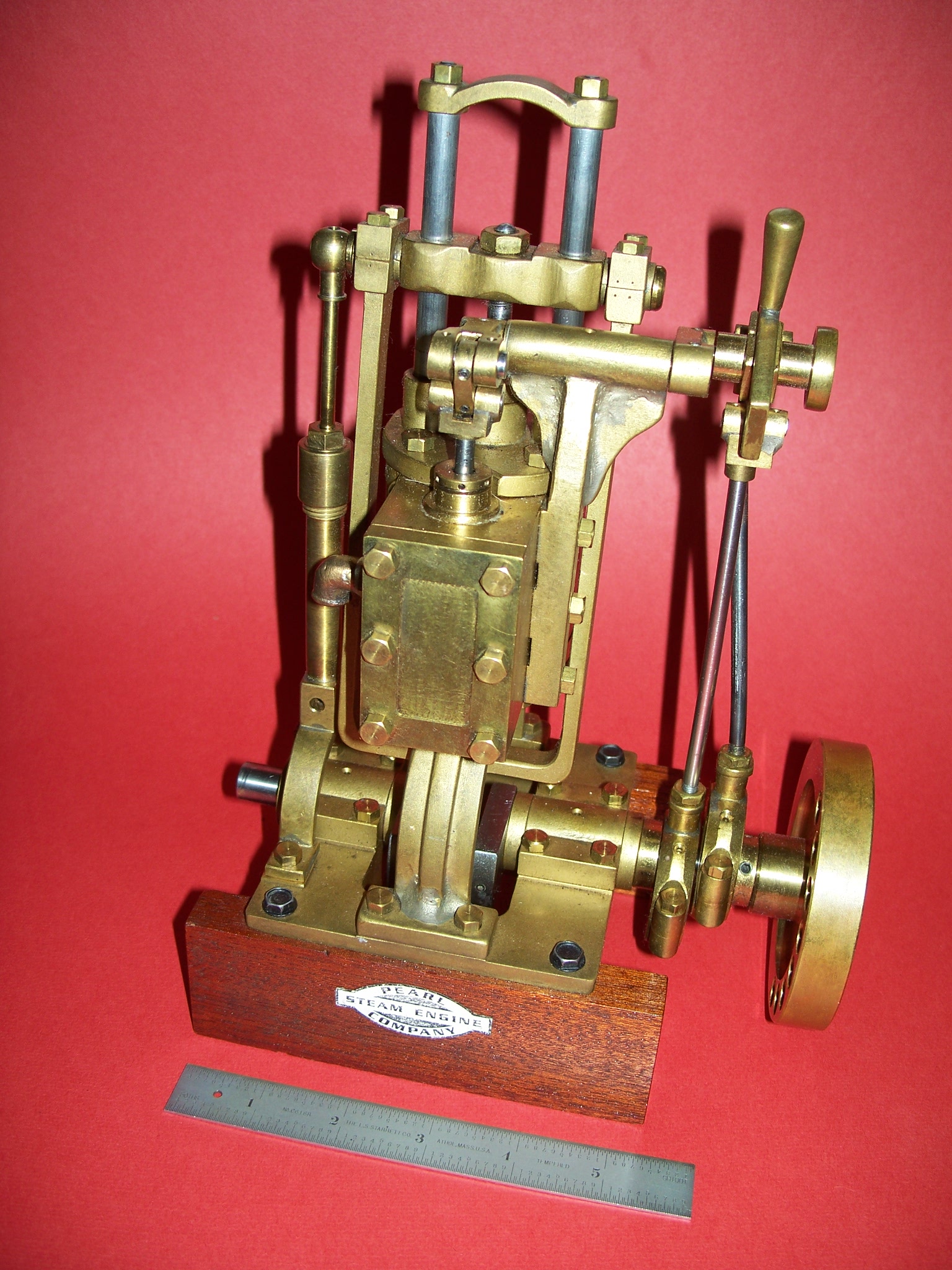

The 3 images below are the Pearl Bronze Twin Cylinder Engine

castings after being machined by the builder and ready for assembly.

The

Pearl Bronze Single Cylinder Engine castings are half in number.

BLUEPRINTS

The machining blueprints package is INCLUDED when either of the PEARL casting kits is purchased. The machining blueprints package of (48) 8 ½” by 11” drawings is available separately. Good for both the single cylinder engine and the twin cylinder engine.

Cost of the blueprints including postage in the UNITED STATES is $100.00

Cost of the blueprints including airmail postage INTERNATIONALLY is $125.00

100% of the blueprints package purchase price will be credited to a future PEARL castings purchase.

PEARL SINGLE CYLINDER MAKE-UP FEED WATER PUMP

As shown on the PEARL single cylinder engine image, the pump as a complete castings kit is available optionally. The kit includes the bronze castings, machining drawings, packing and fasteners. Valves specific to your installation are not included.

The MAKE-UP FEED WATER PUMP kit is designed to fit the PEARL Single Cylinder engine.

Cost of the PEARL MAKE-UP FEED WATER PUMP CASTING KIT is $165.00

WARRANTY

Your satisfaction is our goal. You may return your PEARL castings in their unused and original condition within 30 days after shipment for a refund of the castings price.

We warrant PEARL castings against defects in material for 30 days.

You alone are responsible for determining the accuracy and appropriateness of the castings as well as their safe use.

SHIPPING

We use Federal Express, United Parcel Service and U.S. Mail.

We ship internationally. Please contact us for a quote.

CASTINGS, COMPLETE KIT PRICING IN U.S. DOLLARS

Cost of PEARL Complete Castings Kits (less shipping):

Pricing and specifications are subject to change without notice.

Single Cylinder, all bronze $1920.00

Twin Cylinder, all bronze $3685.00

Email: PearlEngine@Gmail.com

Phone: 802-467-3205

THE ZENITH MARINE STEAM ENGINE

ZENITH ENGINE BACKGROUND

In the 1870’s, the Herreshoff brothers Nathanael Greene and John Brown expanded their sailboat building company to include steam powered craft. Shortly thereafter, the world traveled to Bristol, Rhode Island to the Herreshoff Manufacturing Company for some of the finest examples of sail and steam powered vessels ever seen.

Personal steam yachts were built for the leaders of industry. The first torpedo boats were supplied to various governments. Steam launches were built as well.

The ZENITH marine steam engine is an accurate replica of a circa 1876 Herreshoff 2 ½ by 5 steam launch engine. The blueprints and foundry patterns are based on an actual example. No effort was spared to bring this particular engine back from its legendary history.

FEATURES

Light reciprocating parts to eliminate vibration

Large crank pins and main bearings for longevity

Smooth flowing steam passages cast in at the foundry simplifies machining

Long connecting rod to reduce wear

Bronze engine frame for low total weight and increased strength

Cast iron cylinder assembly for superior steam performance

Direction easily reversed with its slip eccentric

The original engine and our ZENITH demonstrate for its era and now:

Genius in innovation

Beautiful in form

Powerful and efficient

Simple in design

SPECIFICATIONS

ZENITH engine specifications:

Bore and stroke: 2 ½” by 5”

Steam line: ¾” IPT steam, 1” IPT exhaust

Dimensions: 15” long, 11” wide, 33” high

Weight: 78 pounds

Powering your steam launch:

The ZENITH marine engine will easily power your 23 foot launch. The engine

develops high torque at low engine speed and is quiet in operation.

Prime Mover:

The ZENITH engine can also be used to run shop machinery, pump water, generate electricity and power mills. The ZENITH is reliable and efficient.

COMPARE:

When comparing other steam engines, note the ZENITH engine develops its horsepower and torque at low RPM. Many manufacturers over-rate and claim higher horsepower with the same bore and stroke. Look at their higher RPM requirement.

Longevity, Economy and Reliability are hallmarks of the ZENITH.

BUILDER NOTES

The ZENITH engine is for the experienced builder with an intermediate level of skill. The included machining blueprints are easy to read. Typically each part is on its own page.

All the castings are included. The engine’s frame is of high strength bronze. The cylinder assembly is of high strength cast iron. Round and flat stock is supplied by the builder.

The cored cylinder casting simplifies its machining as all the internal passages

are cast in place at the foundry. The bronze and iron castings are supplied steel shot

blasted and are not rough ground.

The built-up crankshaft construction using superior materials allows for easy alignment. Valves, fittings, piping and lubricators are specific to your installation and not included.

Zenith Castings Kit, Bronze And Iron

BLUEPRINTS

The machining blueprints package is INCLUDED when the ZENITH castings are purchased. The package of (28) 11” by 17” drawings is available separately.

Cost of the blueprints including postage in the UNITED STATES is $100.00

Cost of the blueprints including airmail postage INTERNATIONALLY is $125.00

100% of the blueprints package purchase price will be credited to a future ZENITH castings purchase.

WARRANTY

Your satisfaction is our goal. You may return your ZENITH castings in their unused and original condition within 30 days after shipment for a refund of the castings price.

We warrant ZENITH castings against defects in material for 30 days.

You alone are responsible for determining the accuracy and appropriateness of the castings as well as their safe use.

SHIPPING

We use Federal Express, United Parcel Service and U.S. Mail.

We ship internationally. Please contact us for a quote.

CASTINGS PRICING (in U.S. dollars)

Pricing and specifications are subject to change without notice.

Pricing includes the machining blueprints package.

Cost of the ZENITH castings (less shipping) is $1965.00

Email: PearlEngine@Gmail.com

Phone: 802-467-3205

VIDEO LINKS:

Pearl Steam Engines can be seen running on the following links:

Single Cylinder (all bronze example) http://www.imgur.com/a/1Tlko

Twin Cylinder (cast iron and bronze example) http://www.imgur.com/qApu2Hg

The Zenith as built by David Young: https://imgur.com/UYWClVp